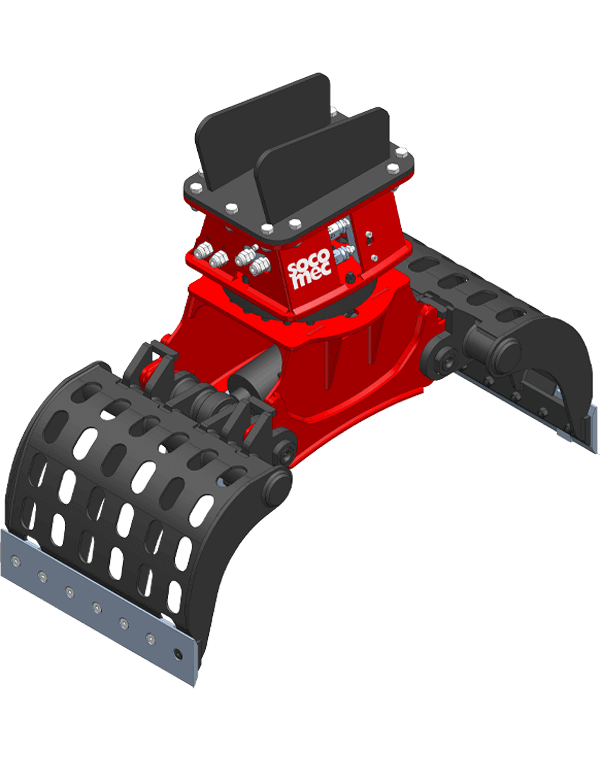

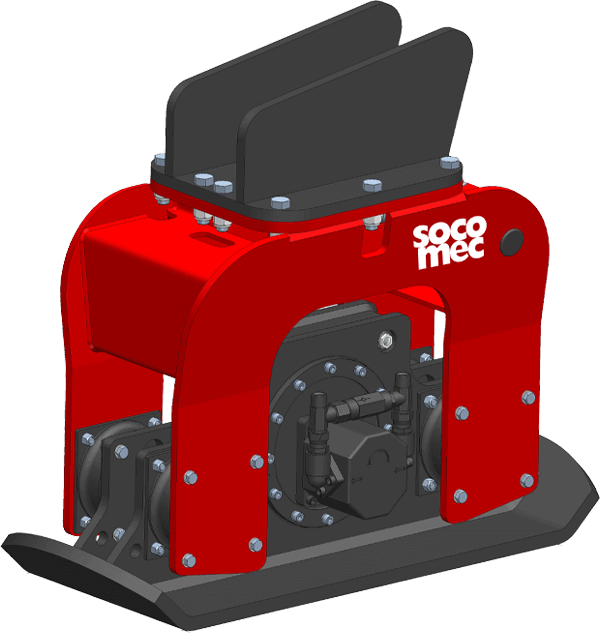

The screening bucket GV-1500 is an innovative machine that solves multiple problems in the field of selection of inert materials of various sizes, of pebbles along water courses, waste material after stable demolitions, land reclamation and beaches.

The material excavated and after selected through screening and can be reused to stabilize the ground without resorting to the extracted material in the quarry, much more expensive.

The screening bucket GV-1500 performs its function with the rotation of the drum, through planetary gear unit actuated by hydraulic motor; with this rotary movement of the material collected by the bucket is rotated on itself; so doing inside the screen, there remains only the size of material further to the holes of the screen used.

The particular shape of the screen allows to have a greater sieving surface that significantly increases productivity and with a higher yield than any other equipment grill.

The extreme ease of the screen replacing with various sizes of mesh (30x30mm – 180x180mm) allows a selection of various size materials with a minimum lost of time. The screening bucket goes installed on any excavator model from 13-25 tons in weight, changing only the mounting plate; It works with the system oil of the hydraulic breaker and is built in a high mechanical strength steel. It meets the essential requirements of european standards of CEE Directive 89/392 machines, however improper use of the machine cause serious damage to people and property (General precautions for safety); has a SAE capacity of 0.80 cubic meters and can be combined with a crusher bucket of ITALDEM GF series for the crushing of bigger size of material then screen.